| Payment Type: | T/T,Money Gram,Western Union |

|---|---|

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 30 Days |

Basic Info

Model No.: MCWS-20

Item: Industrial Containerized Sewage Treatment Plant

Place Of Origin: Guangzhou, China

After-sales Service Provided: Video Technical Support, Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Free Spare Parts, Online Support

Warranty: 1 Year

Packing: Seaworthy Package

Color: Silver

Material: Carboon Steel Or Stainless Steel

Power: 220v Or 380v

Processing Capacity(m3/h): 20

Additional Info

Packaging: standard export package

Brand: MeCan

Transportation: Ocean,Land,Air

Place of Origin: China (Mainland)

Supply Ability: 100 sets per month

Port: Guangzhou

Product Description

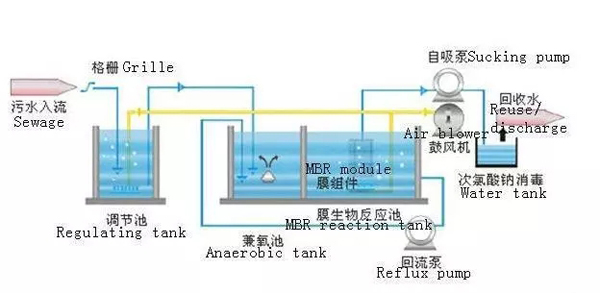

The containerized sewage treatment plant principle is a kind of biochemical treatment which combine activated sludge microbiological method and new biological membrane manner. In treatment process, large bacteria and bacteria membrane update, adopt biological carrier, improve the contact efficiency of micro- organism and pollutant matter in sewage; the whole treatment equipment produce anaerobic-anoxia- oxidation three kind of environment take turns function, improve purified water ability of different kind of microbial population, intensify organism removal and nitrogen and phosphorus removal function.

Technological Process and Features

Sewage → Grille → Regulating pond → MBR Bioreactor → Discharge(reuse)

1. Temperature: 5℃~45℃, average membrane aperture 0.10 μm.

2. PH: 2~12, membrane thickness: 40μm.

3. Outlet water turbidity: <1 NTU , outlet water SS <1mg/L.

4. Membrane area: 8m2, advised gas-water ratio: 25:1~30:1.

5. Operating pressure: -0.01 ~ -0.03MPa.

Features:

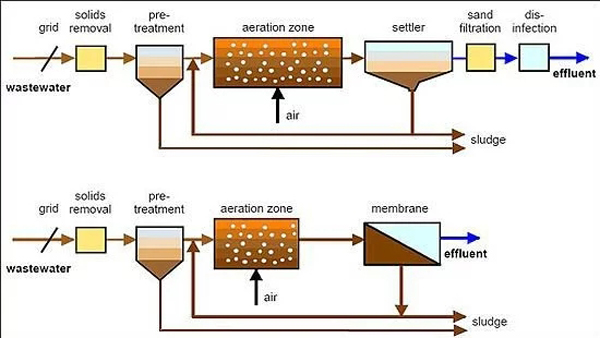

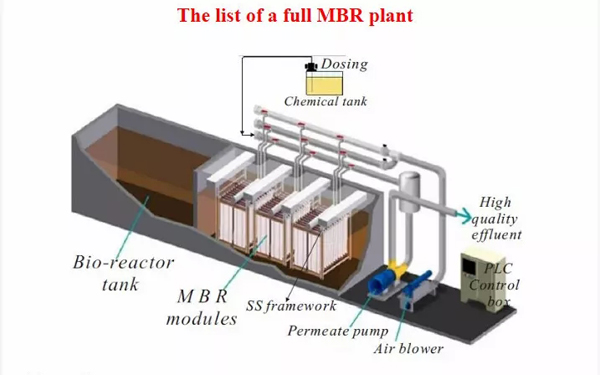

1. Because of the high-efficiency solid-liquid separation, it can efficiently remove the SS, colloidal material and dead microbe in the sewage, no need sedimentation tank, or filter device, nor other solid-liquid separation device.

2. The MBR can make the biomass in biological treatment unit maintain high concentration, thus highly improve the volume loading. Meanwhile, the high efficient membrane separation can shorten the HRT. The device is with a compact structure and small space occupation.

3. MBR can filter out bacteria, part of the harmful material such as virus, it can obviously save dosing disinfection dosage, greatly improve the quality of the output water and reduce the operating cost and widen the scope of application of water.

4. Due to the strong interception function of MBR, it can keep the microbe in the reactor to avoid the loss of all kinds of microbe groups, which is good for the growth of the bacteria (such as the nitrifying bacteria), at the same time, it can lengthen the residence time of difficult degradable macromolecule organics to improve the decomposition so as to make the metabolic system process smoothly. The system has a strong impact resistance and wide suitability.

5. It can realize the completely separation of HRT and SRT. By the extended aeration, it can consume the organics, it can theoretically achieve the effect of no excess sludge emissions, thus reduce the surplus sludge treatment costs significantly.

6. The unique mode of operation makes the membrane surface no blocking, and the cleaning interval time is long. The way to clean the membrane is easy, since the membrane module can be separately cleaned, thus, the maintenance is convenience and simple.

Item/model

MCWS-1

MCWS-3

MCWS-5

MCWS-7.5

MCWS-10

MCWS-15

MCWS-20

MCWS-30

MCWS-40

MCWS-50

Processing

capacity(m3/h)

1

3

5

7.5

10

15

20

30

40

50

Component

quantity

1

1

1

1

2

2

2

3

4

4

Sludge

absorption and primary Sedimentation

(m3/m2

h)

1.8

5.5

9

14

18

27

36

50

82

100

Disinfection

pond (m3)

5.0

14.5

24

36

44

63

83

130

170

200

Surface

loading of secondary sedimentation

pond(m3/m2

h)

1.2

1.3

1.3

1.3

1.3

1.2

1.2

1.5

1.5

1.5

Disinfection

pond (m3)

0.6

1.5

2.8

4

5.5

8

10

15

20

25

Floor

area(m2)

6

20

24

30

50

65

75

115

155

185

The module design make the machine flexible, it is easy to expand the volume.

As a waste water treatment system features simple operation, high automation and modular design, it also has below advantages:

*Save 50% occupying area compared with traditional system.

*Relative high MLSS value(<15g/L)and long residue time for sludge(<60days).

*Stable producing water quality for different inlet water.

*Less sludge residue reduces cost for sludge treatment.

*Low energy consumption, simple cleaning and low operation cost.

CONTACT US

Guangzhou MeCan Medical Limited

Address: Room 510,Yidong Mansion,No.301-303,Huanshi Middle Road,Yuexiu,Guangzhou City,Guangdong,China,Guangzhou,Guangdong

Contact Person: Joe Jiang

Phone:86-20-84835259

Fax: